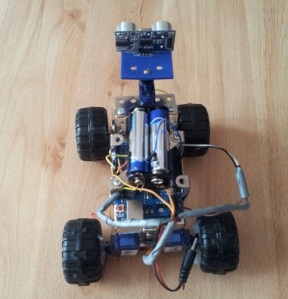

So here is the working version of the robot, I will talk through some of the steps that stopped the bot from working in part 01.

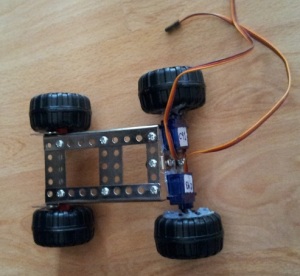

As the wheels are plastic, and my house is all tiles and laminate, the wheels would just spin. Because the Bot uses differential steering grip is a must, as it wouldn’t turn enough. Rather than replace the wheels all together I cut strips out and then, added in little pieces of rubber. Not perfect, but MUCH better.

The main problem for my bot was power, the 9v that I had mounted on the breadboard up top wasn’t enough. So went on ebay and got a few 4 battery pack adapters. As these are fairly bulky I didn’t want to add this on top of the 9v, which I kept to power the Arduino. So I moved the 9v to under the bot, got rid of the breadboard, and have just the battery pack up top now.

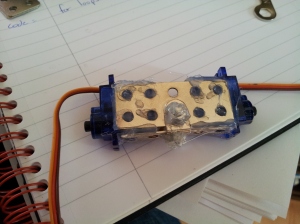

I glued the head servo to a metal bracket, and cut a piece of plastic for the ultrasonic sensor. The pins of the sensor feed through the plastic, as there was much to attach this to.

Couple of pics below to see what the bot looks like now, taped a few wires as they kept being caught on the wheels.

Just so you can see a size comparison of my Bot, Smudge my cat decided to get in on the camera action.

VIDEO —- I will create and upload video in next day or so, just need to tweak code more, then upload that also.